The wider the path, the faster the corner speed

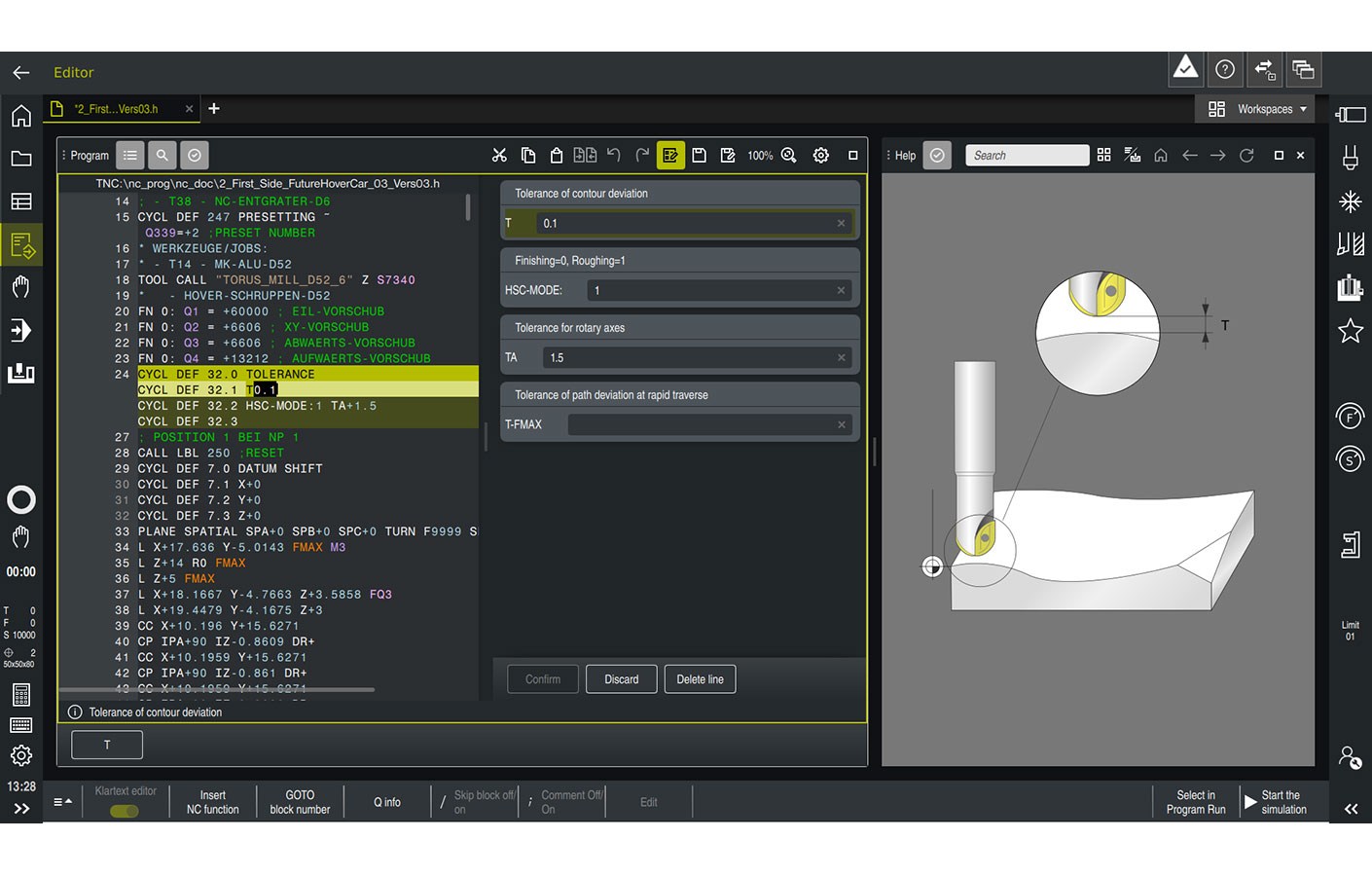

The path deviation T is usually set by the machine tool builder. It defines a default value for the maximum permissible contour deviation. Cycle 32 TOLERANCE enables operators to individually adapt the path deviation T to the specific machining operation by specifying the path width that is available to the control. In this way, operators can directly influence the maximum achievable machining feed rate—and thus the machining time. This is particularly useful for contour elements involving many direction changes, such as typical free-form surfaces.

An example from car racing illustrates the principle: The wider the track is, the faster the race car can go around a turn. The driver chooses the racing line that allows the highest speed through the turn. On a narrow track, in contrast, the driver has no choice of line and is forced to slow down.

Roughing operations, in particular, frequently support wider paths, and thus higher tolerances for the path deviation T. In this way the operator can also increase the maximum possible machining feed rate in narrow places. For finishing, the operator needs to reduce the tolerance value again or reset it to the value defined by the machine tool builder. This is done by programming Cycle 32 TOLERANCE once again with a low value or without a value.