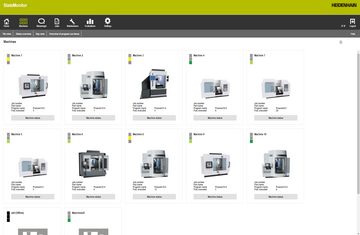

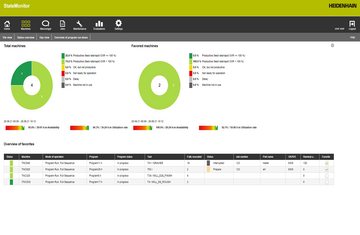

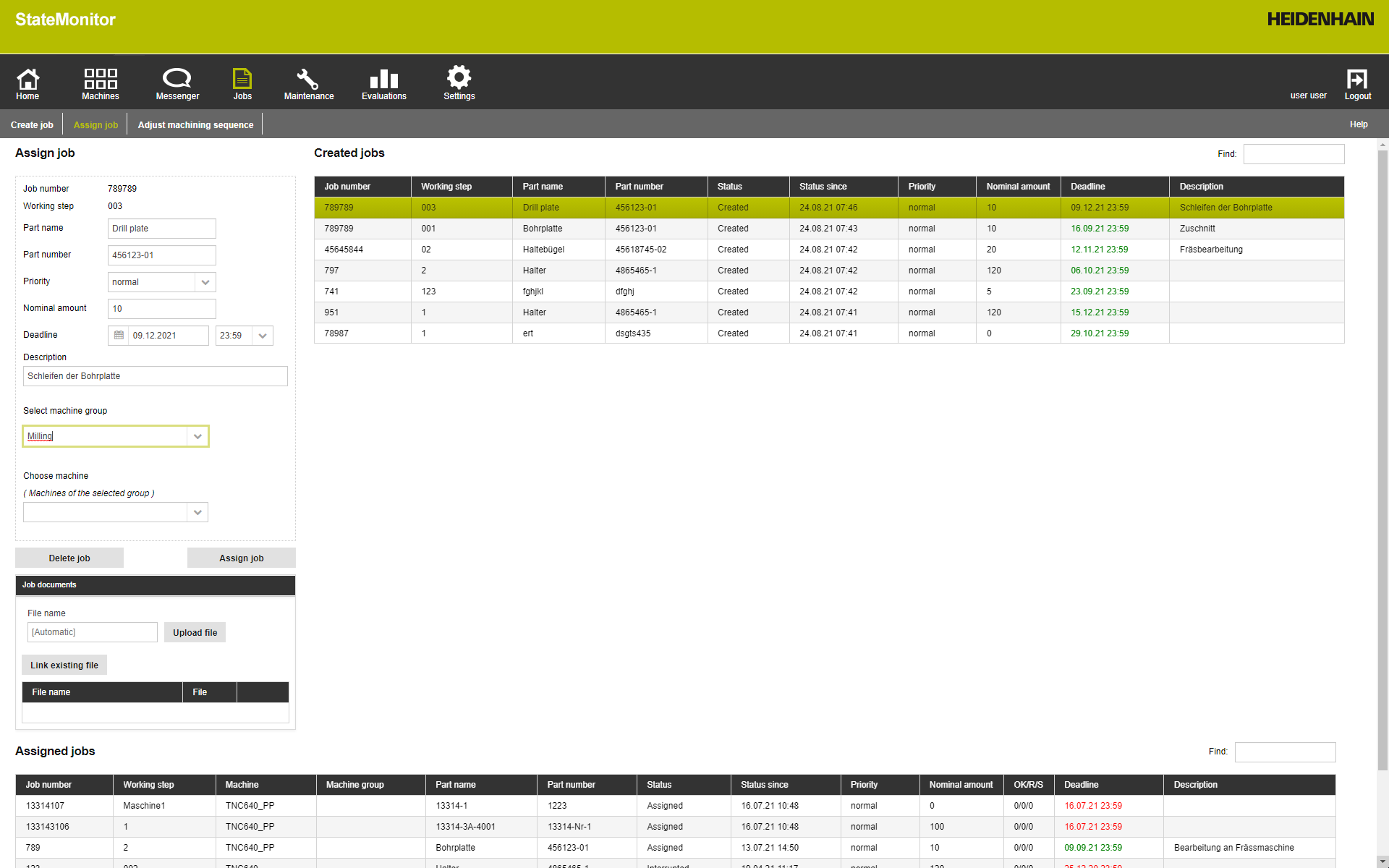

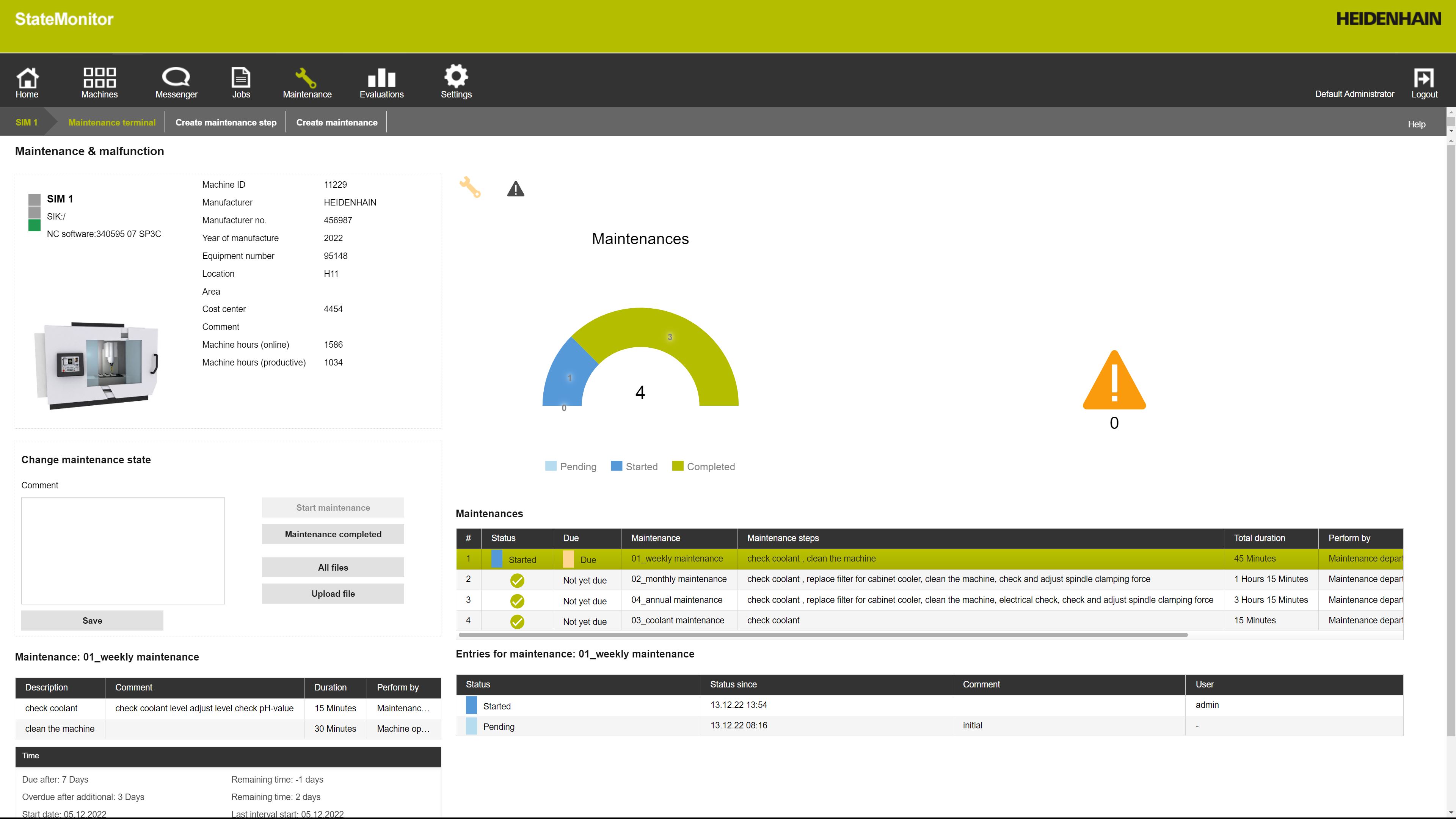

Intuitive user interface

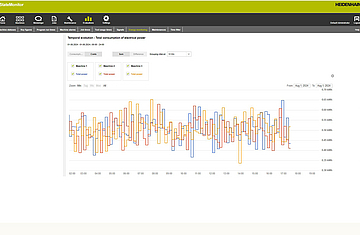

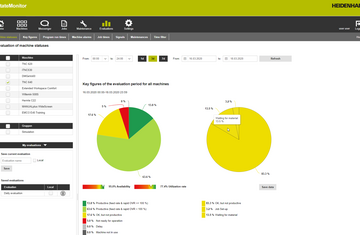

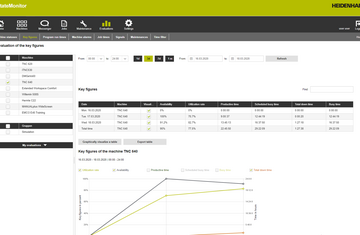

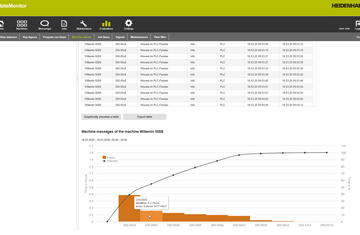

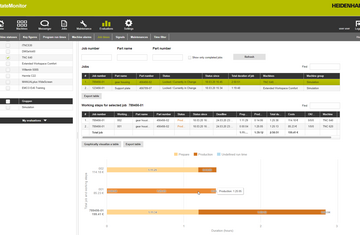

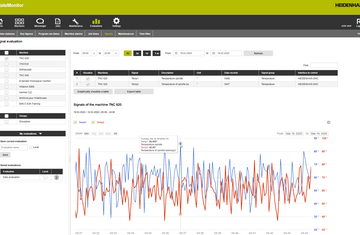

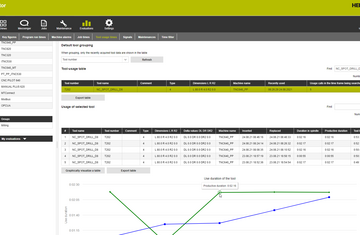

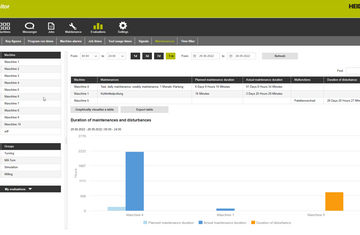

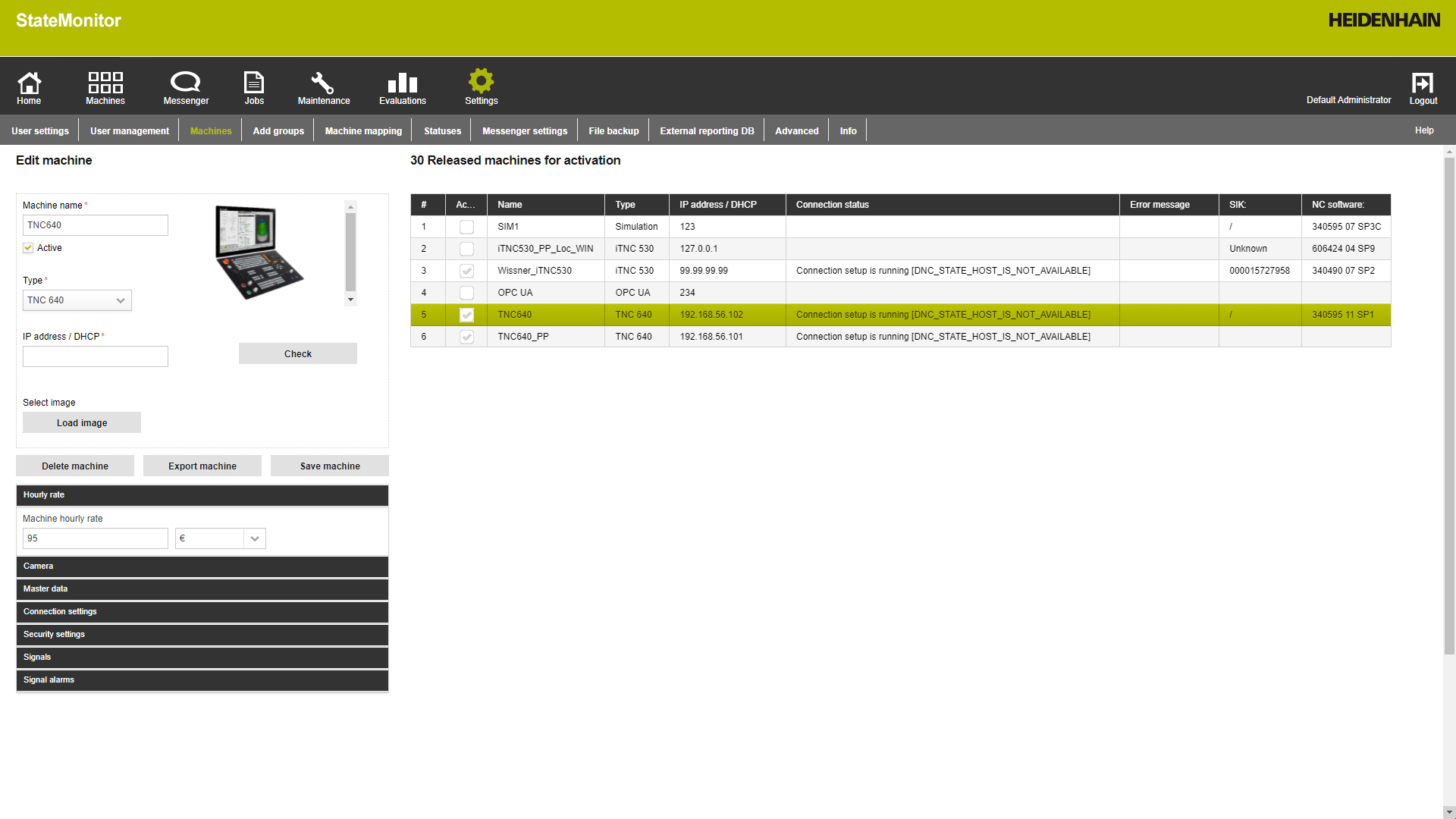

Practical, intuitive, and user-friendly: the StateMonitor user interface gives you a rapid overview of the current production status. In the Machines, Messenger, Jobs, Maintenance, and Evaluations menus, you’ll find all of the functions you need to enable the individualized collection, evaluation, and analysis of machine data, thereby allowing you to keep a continual an eye on machine availability and the utilization rate.

Intuitive user interface

Practical, intuitive, and user-friendly: the StateMonitor user interface gives you a rapid overview of the current production status. In the Machines, Messenger, Jobs, Maintenance, and Evaluations menus, you’ll find all of the functions you need to enable the individualized collection, evaluation, and analysis of machine data, thereby allowing you to keep a continual an eye on machine availability and the utilization rate.