Batch Process Manager:

Plan the production sequence

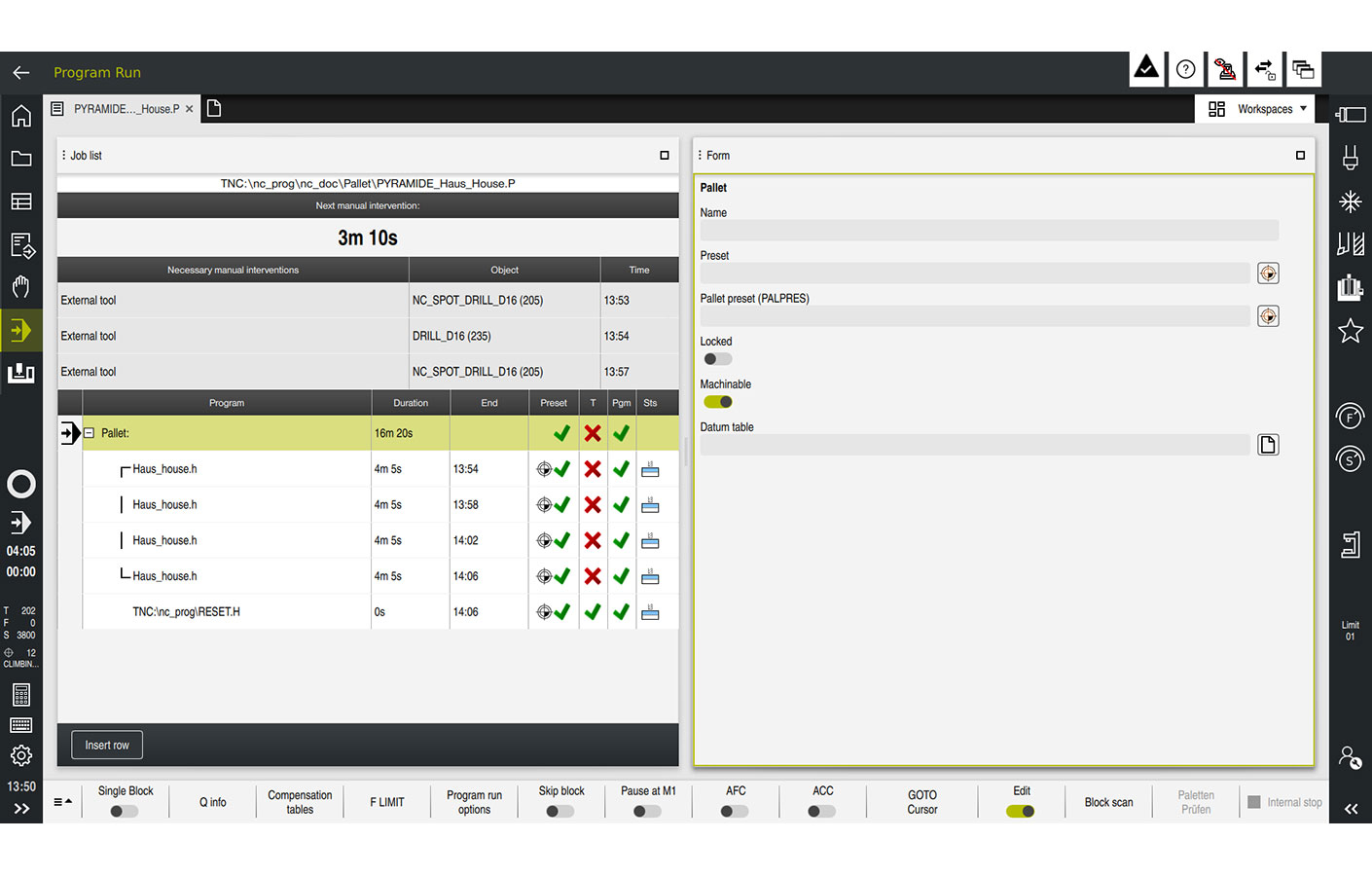

The TNC 640 provides a number of powerful functions for pallet machining and for the serial production of workpieces. One of these functions is the Batch Process Manager (Option 154), which allows you to plan the production process in advance.

Organize shifts for days, nights, and weekends

Organize shifts for days, nights and weekends

With the Batch Process Manager, you can organize your pending jobs with speed, ease, and process reliability. First, you create a jobs list. Simply enter the planned jobs for the upcoming night shift, entire day, or weekend. The Batch Process Manager then analyzes the jobs and provides critical information about the anticipated production sequence, including the following:

- How long will the machines be in use?

- When will manual interventions be needed?

Detect critical machining factors in advance

The control automatically determines whether all of the requirements for smooth execution of the entered jobs are fulfilled:

- Is a preset entered at the pallet, program, or fixture level?

- Does the NC program run in the simulation without an error message?

- Which tools are still needed, and which ones lack sufficient service life?

Seeing how long your jobs will take

The Batch Process Manager shows you at a glance how long your jobs list will take to complete. The Batch Process Manager repeats its analyses cyclically so that updated data is regularly displayed.

The Batch Process Manager will inform you in advance about the following:

- The machining sequence

- The time of the next manual intervention

- Program duration and run time

- Status information regarding the preset, tool, and NC program

For automation and single-part production

Although primarily designed for machine tools featuring automation, the Batch Process Manager also makes sense for use in classic single-part production. This is because the abovementioned process elements can also be used for machines without pallets.

You simply tell the Batch Process Manager how the machine should behave at the end of an NC program:

- For automated production, the next pallet is loaded, and machining proceeds automatically.

- For single-part production without pallets, you configure the system settings such that the machine operator can manually set up the next workpiece and start the ensuing machining operation.

The NC programs are executed either through the pallet management function or in the accustomed manner via the individual NC program in the Program Run, Full Sequence operating mode.