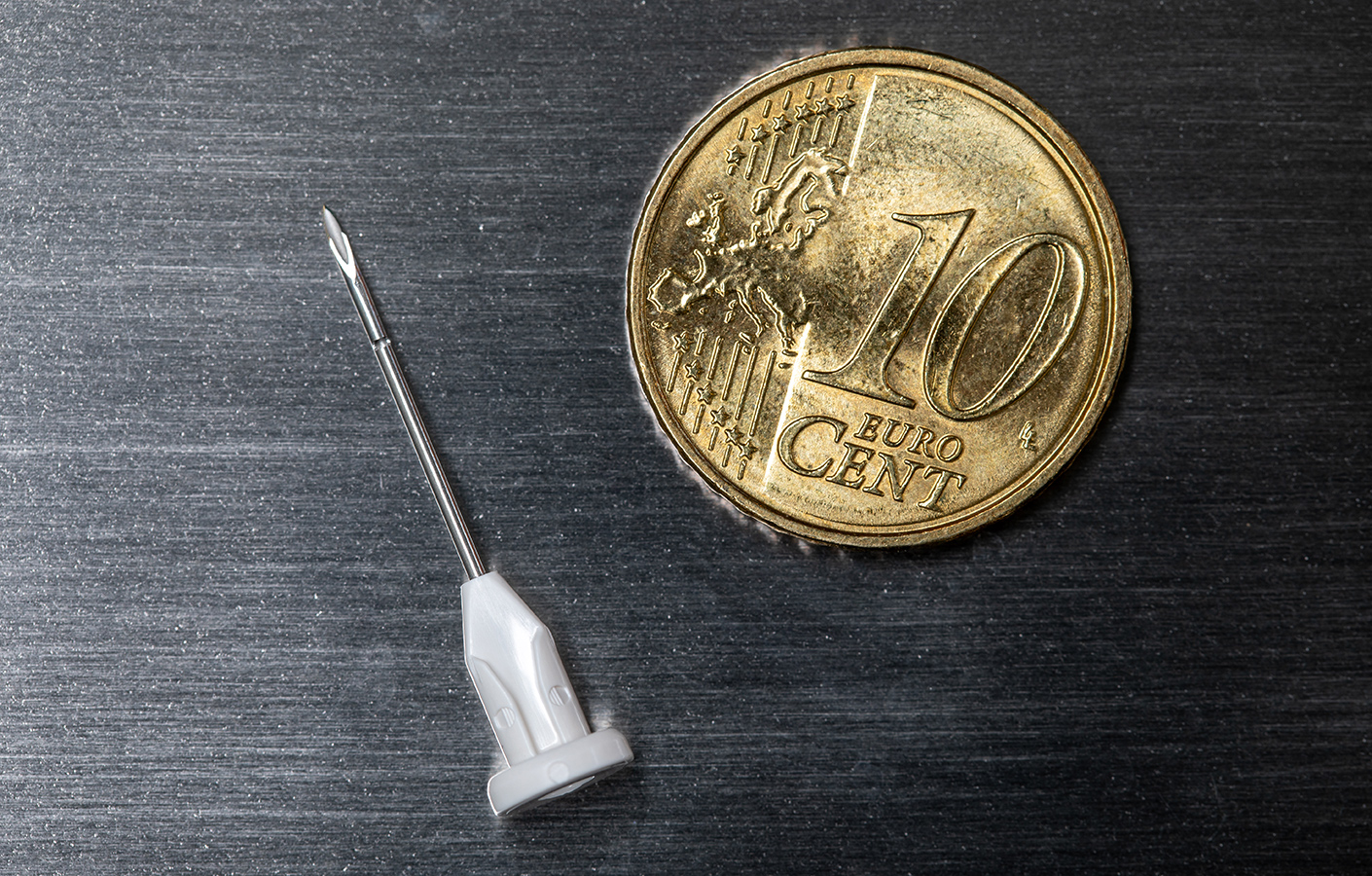

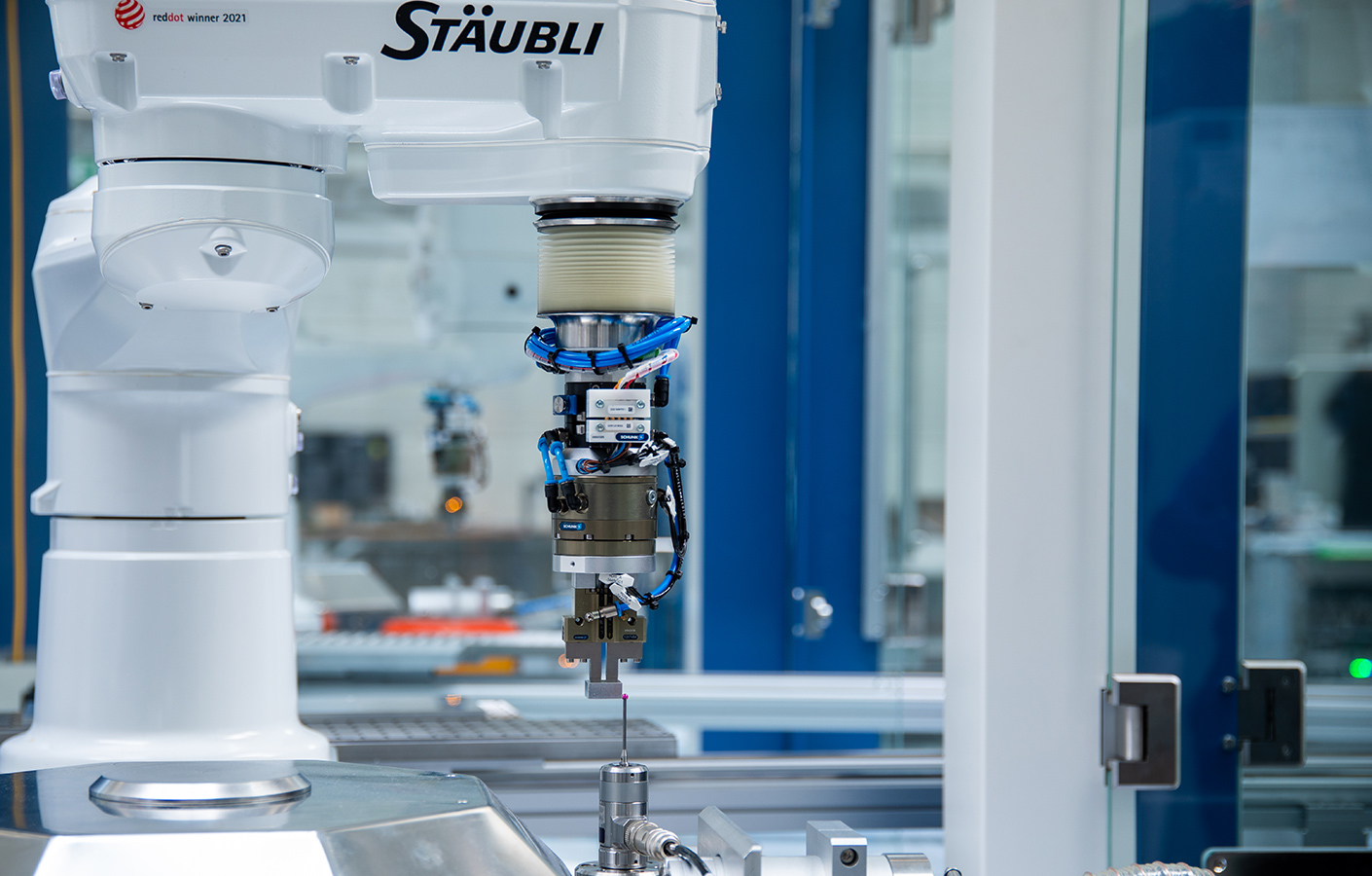

The described needle manufacturing facility is part of an integrated production line for the manufacture of single-use applicators in ophthalmology. The IMSTEC solution has two identical production lines in order to produce the required quantities.

The conveyed cannulas are further processed in the following steps:

Handling in separation magazines

Positioning via turning units in front of a sensor

Injection molding

Cleaning and measuring on a first rotary indexing table

Cleaning and optical testing of the channel with multiple cameras on a second rotary indexing table

Rotating the needle to a vertical position

Optical inspection of straightness, any damage to the needle tip and bevel, and any contamination, using multiple cameras

Transfer of the good parts to another facility for further processing

About IMSTec

IMSTec GmbH is located in Klein-Winternheim, near Mainz in the German state of Rhineland-Palatinate. As a machine manufacturer, its specialty is fully automated production lines, particularly for medical and pharmaceutical technology, as well as for the semiconductor industry. IMSTec emphasizes robotic solutions for such facilities, since they offer the necessary degree of flexibility for the special tasks and challenges of the individual projects. By developing 3D models, the use of the robots can already be prepared in detail during the development and design phase.

IMSTec GmbH

Auf dem Langloos 10

55270 Klein-Winternheim, Germany

+49 6136 99441 10

info@imstec.de

www.imstec.de

About ITG

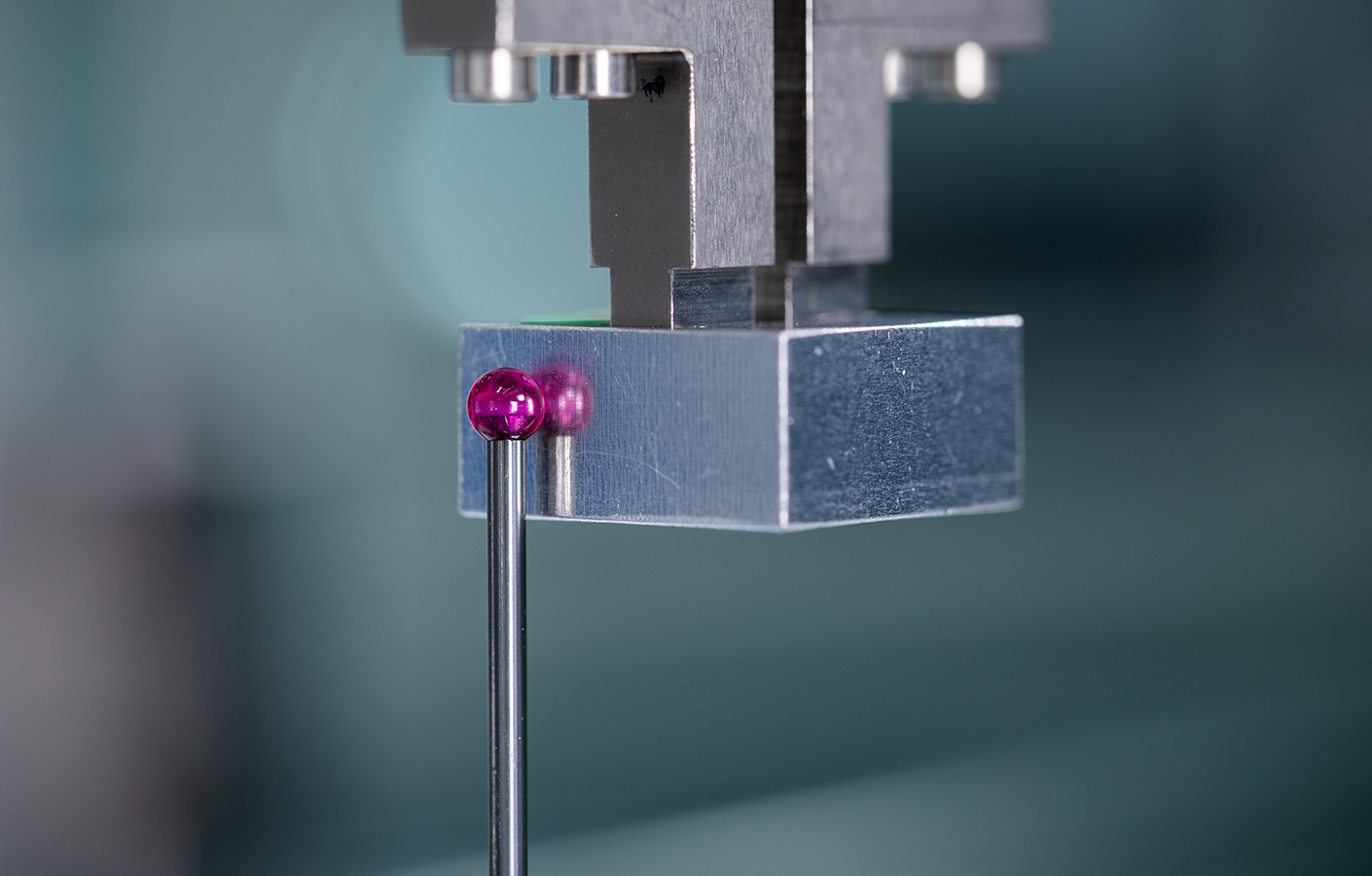

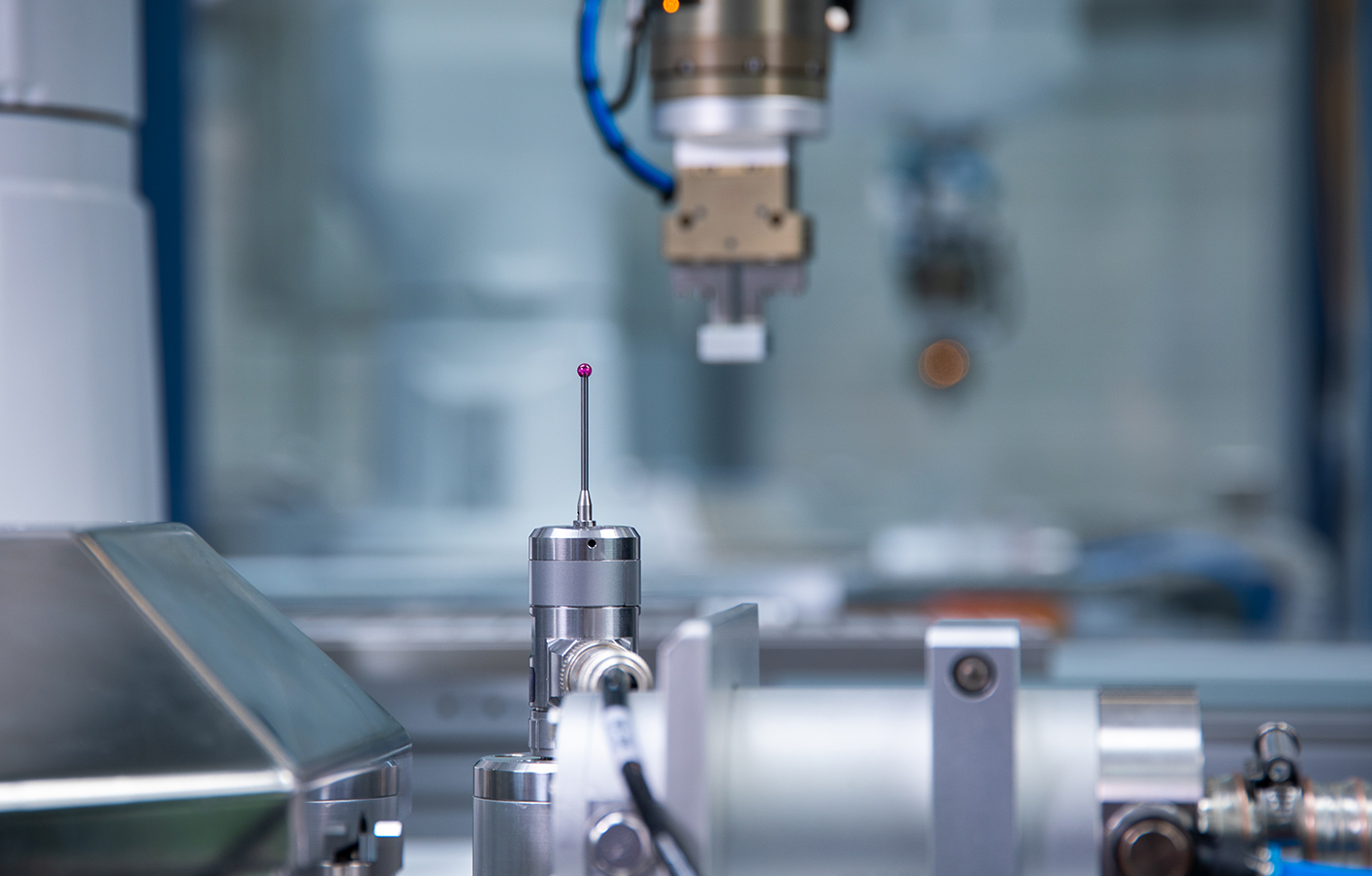

In Bayreuth, Germany, the team at ITG Innovative Technologies GmbH is dedicated to optimizing production facilities with robots. In addition to comprehensive consulting services as well as numerous other services relating to robotics, the company's portfolio includes the iMS intelligent measuring system for fully automatic diagnosis and independent calibration of the entire robot cell.

About iMS

iMS is an inline measuring system for calibrating 6-axis articulated robots and SCARA robots, various special kinematic designs, and external axes. Its capabilities include:

- Analysis of robots, including grippers, and optimization at the press of a button without requiring specialized knowledge

- Automatic "teaching" of the robot application

- Automated testing and correction of the robot kinematics, the robot gripper and the periphery of the robot cell after collision, wear or robot replacement

- Evaluations for predictive maintenance

- Exact locating of errors in the work envelope

ITG Innovative Technologies GmbH

Spinnereistraße 5a

95445 Bayreuth, Germany

+49 921 786 303-700

info@i-t-gmbh.com

www.i-t-gmbh.com